Multiply yourself

with AI in production.

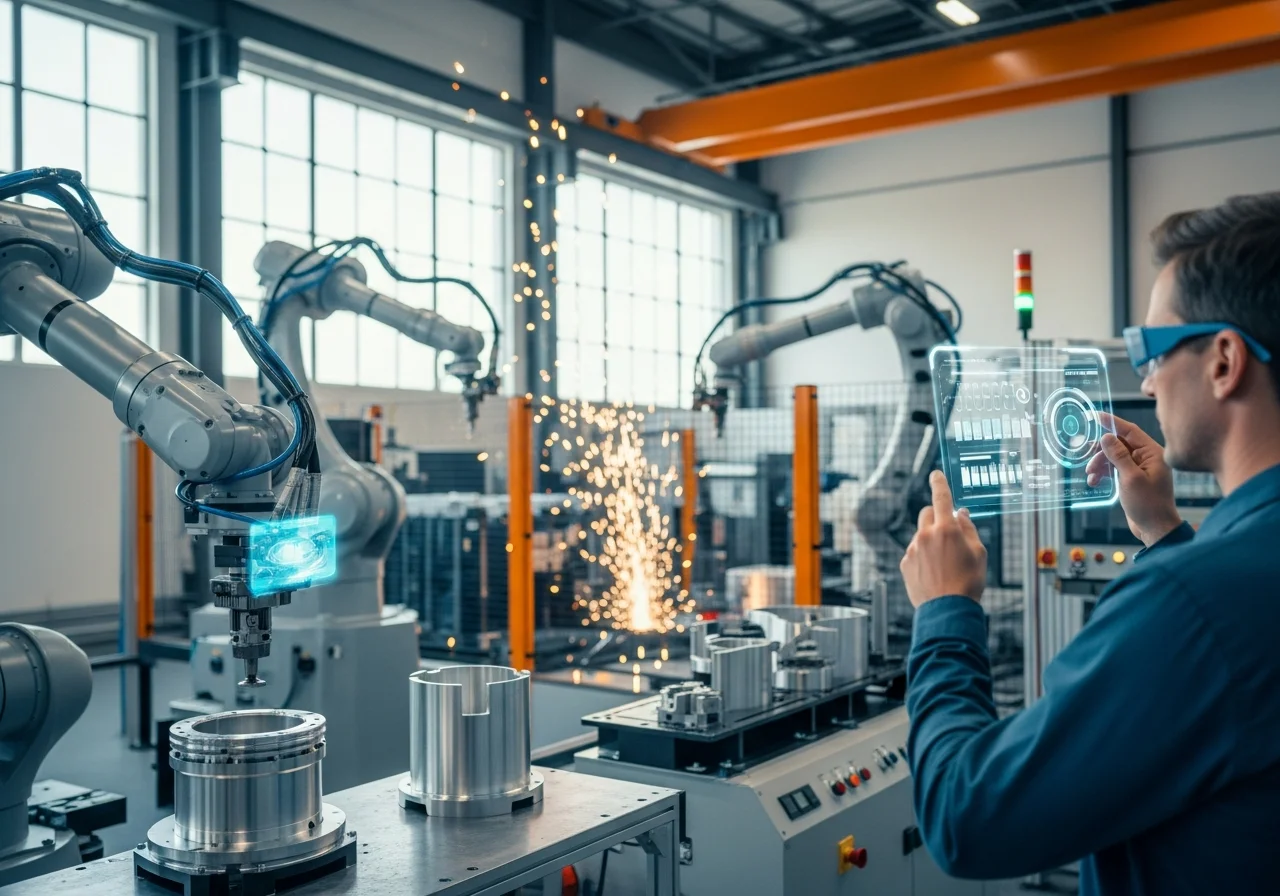

AI models like GPT-5.1, Claude Opus 4.5 and computer vision make your production smarter. From predictive maintenance to quality control and smart quotations: we help you build the right AI solution. Practical and measurable.

Why start with AI in manufacturing now?

The technology is proven, the ROI is measurable and the competition is not waiting.

Predictive maintenance

AI analyses sensor data and predicts failures before they occur. Less unplanned downtime, lower maintenance costs.

Quality control

Computer vision detects deviations in real-time. Faster, more consistent and more accurate than manual inspection.

Smart quotations

AI calculates complex quotations in minutes. Learns from historical data, adjusts prices based on capacity and lead times.

Production optimisation

AI optimises planning, minimises waste and increases OEE. Real-time insights for better decisions.

From pilot to production

Manufacturing is leading in AI adoption. According to McKinsey, manufacturers using AI can increase productivity by 20-30% and reduce maintenance costs by 10-40%. And the technology is developing rapidly.

The latest AI models like GPT-5.1, Gemini 3 and Claude Opus 4.5 understand technical documentation, manuals and product specifications. Combine this with computer vision and sensor data, and you have a smart factory that optimises itself.

Concrete results

Less downtime: predictive maintenance reduces unplanned downtime by 35-45%.

Higher quality: AI inspection detects defects that the human eye misses.

Faster quotations: complex calculations in minutes instead of days.

Better planning: AI optimises production schedules and minimises waste.

How we implement AI in your production environment.

From initial exploration to working solution: we guide you through the entire process with a pragmatic approach.

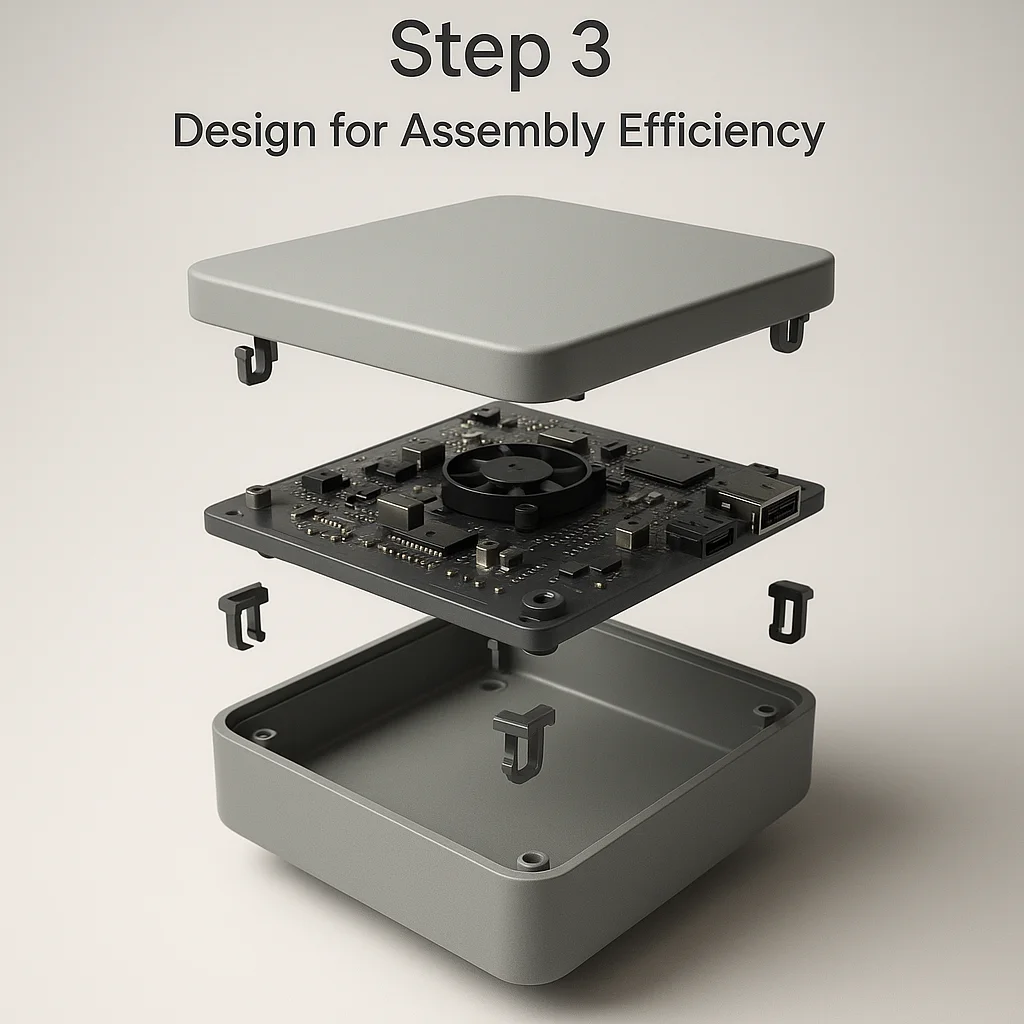

Use case inventory.

Where are the biggest opportunities? We walk the shop floor with you and identify processes with the highest impact: unplanned downtime, quality issues or time-consuming calculations.

Proof of Concept.

Within weeks we build a working prototype. With real machine data or production information. We measure the results directly.

Integration & security.

We connect AI to your existing systems: ERP, MES, PLCs or SCADA. Always with attention to cybersecurity and OT/IT separation.

Scalable rollout.

From one machine to the entire factory. We train operators, monitor performance and continuously optimise. Start small, scale up when it works.

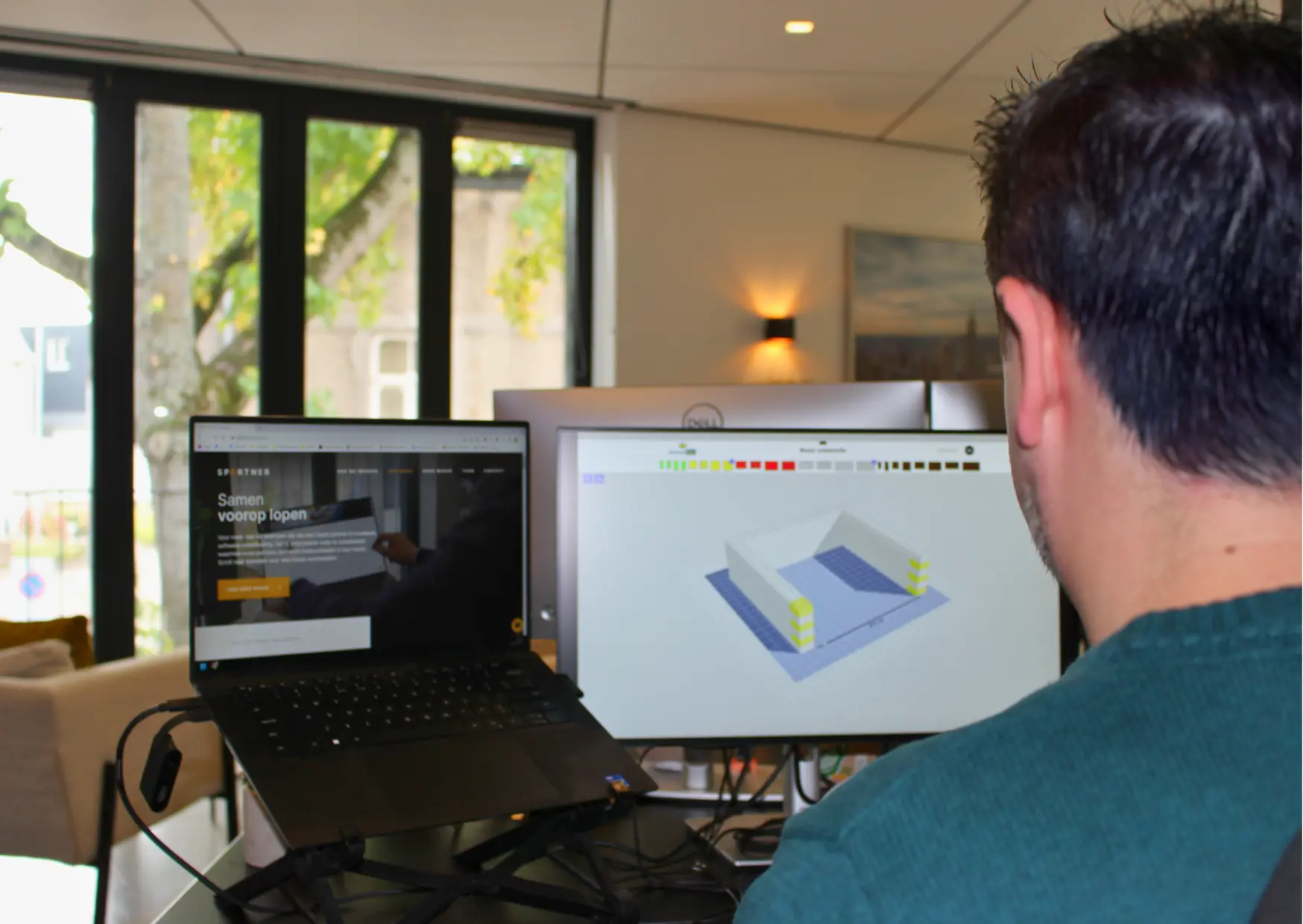

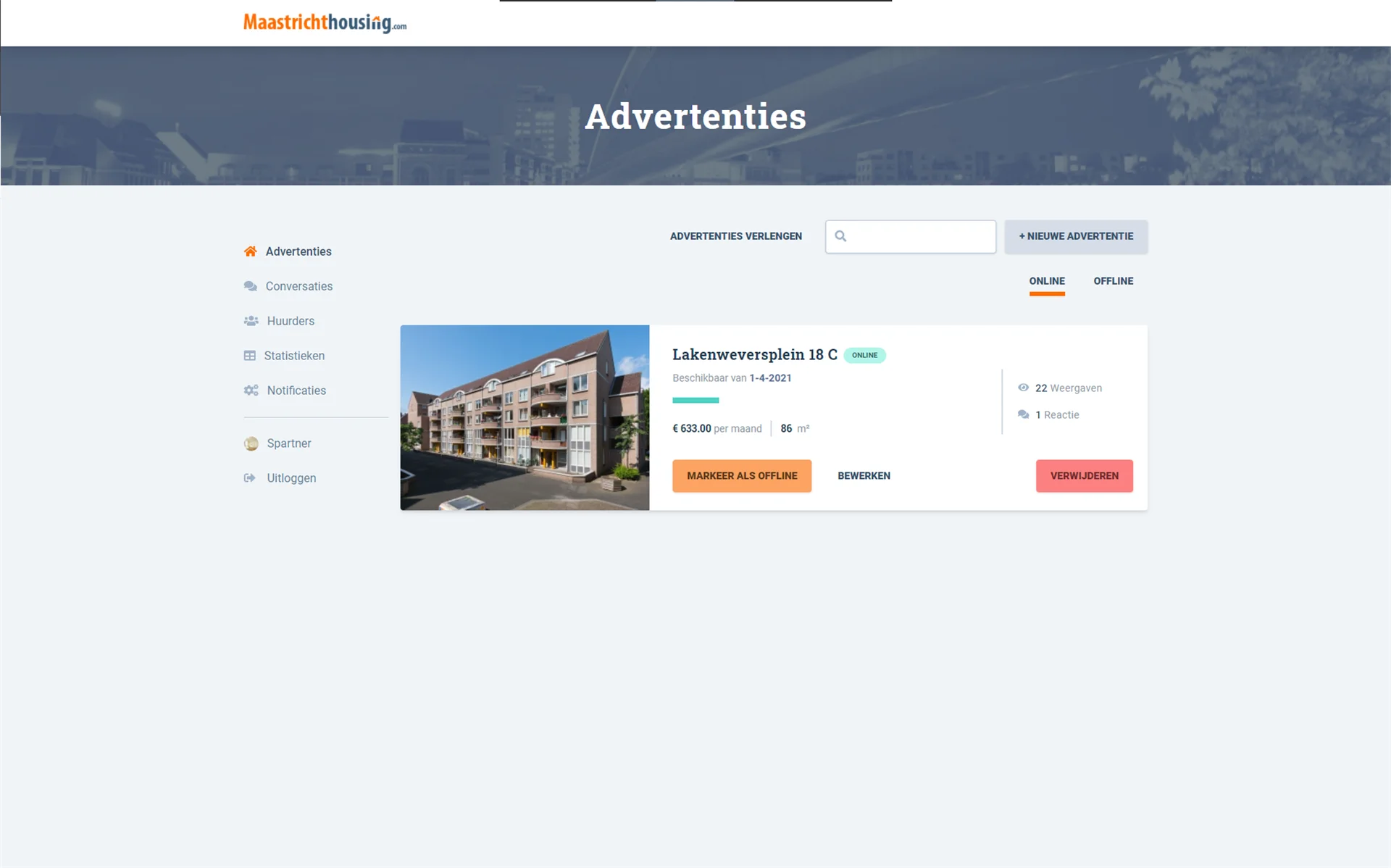

Projects in manufacturing

We have been working with companies in the production sector for years. From 3D configurators to smart calculation tools – always focused on measurable results.

Predictive maintenance

AI analyses sensor data from machines and predicts when parts need to be replaced. No more unplanned downtime, but scheduled maintenance at the optimal time.

Measurable results

35-45% less unplanned downtime

10-40% lower maintenance costs

Longer machine lifespan

Computer vision quality control

Cameras and AI inspect products in real-time on the production line. Defects are automatically detected and rejected, faster and more consistently than manual inspection.

Benefits

AI sees deviations that the human eye misses. Works 24/7 without fatigue. Every inspection is documented for quality reports.

Smart calculation & quotations

AI learns from historical quotations and calculates complex products in minutes. Takes into account material costs, capacity, lead times and margins.

Customised for your business

We train AI on your cost calculations and margin determination. The result: faster quotations that are more profitable.

AI expertise for manufacturing

From concept to implementation.

We combine AI knowledge with understanding of production processes. Our approach: start small, measurable results, and scale up what works. Whether you want predictive maintenance or a smart calculation tool – we think along and build through.

Frequently asked questions about AI in production

Integration with existing systems, cybersecurity, ROI – we understand there are many questions. Here are the most common ones.

Does AI work with our existing machines and systems?

Almost always. We build integrations with ERP systems (SAP, Microsoft Dynamics), MES, PLCs and SCADA. We can often also equip older machines with sensors and connectivity.

What about cybersecurity?

Cybersecurity is our top priority. We respect OT/IT separation, work with encrypted connections and can run on-premise. Our solutions comply with IEC 62443 guidelines.

What is the ROI of AI in production?

The ROI depends heavily on the use case. Predictive maintenance typically saves 10-40% on maintenance costs. Quality control reduces waste. Smart quotations increase hit rate. We always measure the baseline beforehand so you can demonstrate results.

What does an AI implementation cost?

We often start a proof of concept from €15,000 to €30,000. Full implementations vary greatly depending on scope, number of machines and integrations. We work transparently with fixed prices or time and materials.

Do we need data science knowledge ourselves?

No. We take care of the technical side. However, it is important that your team contributes process knowledge – they know where the pain is and what is normal. The combination of domain knowledge and AI expertise delivers the best results.

How long does an implementation take?

A proof of concept is often ready in 6-10 weeks. From POC to production takes 2-4 months, depending on integrations and rollout. Our approach: start small, deliver value fast, expand what works.

.webp)