While metal wholesalers struggle with razor-thin margins and erratic lead times, AI is emerging as the silent powerhouse inside modern ERP systems. In this blog I guide you through the latest developments, share real-world examples from our own code kitchen 🤓 and give you concrete steps to start making a difference today.

Can AI make your ERP smarter?

While metal wholesalers struggle with razor-thin margins and erratic lead times, AI is emerging as the silent powerhouse inside modern ERP systems. In this blog I guide you through the latest developments, share real-world examples from our own code kitchen 🤓 and give you concrete steps to start making a difference today.

Steel gets smart

Why jump in now?

AI cuts waste and stress

Demand forecasting By training neural networks on order and market data you can spot seasonal spikes weeks in advance. Less safety stock, more cash flow.

Dynamic purchasing Nickel price swings? Machine-learning models scan real-time commodity feeds and suggest the best moment to buy.

Smart cutting plan Optimisation algorithms calculate the most efficient sawing or laser-cutting pattern, reducing scrap by as much as 15 %.

Proactive service Sensor data from warehouse cranes predicts breakdowns. Downtime becomes planned maintenance instead of a 2:00 am emergency call-out.

The AI wave in ERP land

From dashboards to dialogue

I recently read about Microsoft Dynamics 365 Copilot: a chat window in your ERP that not only shows KPIs but also suggests how to clear backlogs. SAP has done something similar with Joule, and even open-source player Odoo has offered generative AI apps since Q2-2024. All the big vendors are sprinting to plug AI features into places where we used to write queries by hand. The interesting bit is that this is no longer a marketing gimmick; customers are actually seeing shorter picking times and more accurate MRP runs.

Why this hits metal wholesalers in particular

Margins are thin, so every predicted deviation counts.

Prices for steel, aluminium and copper can change daily.

Customers want customised bundles, not standard boxes.

AI models excel in variable environments with plenty of data—exactly the playing field of metal wholesalers.

A real-world example

What we do is combine historical order lines (item numbers, alloys, dimensions) with commodity prices and macro-economic indices. An LSTM network forecasts demand volumes per product group for the next eight weeks. In one pilot a client saw their dead stock drop by 11 %. No rocket-science code wizards—just smart data cleansing and fine-tuning.

Technical deep dive: how do you plug AI into a Laravel stack?

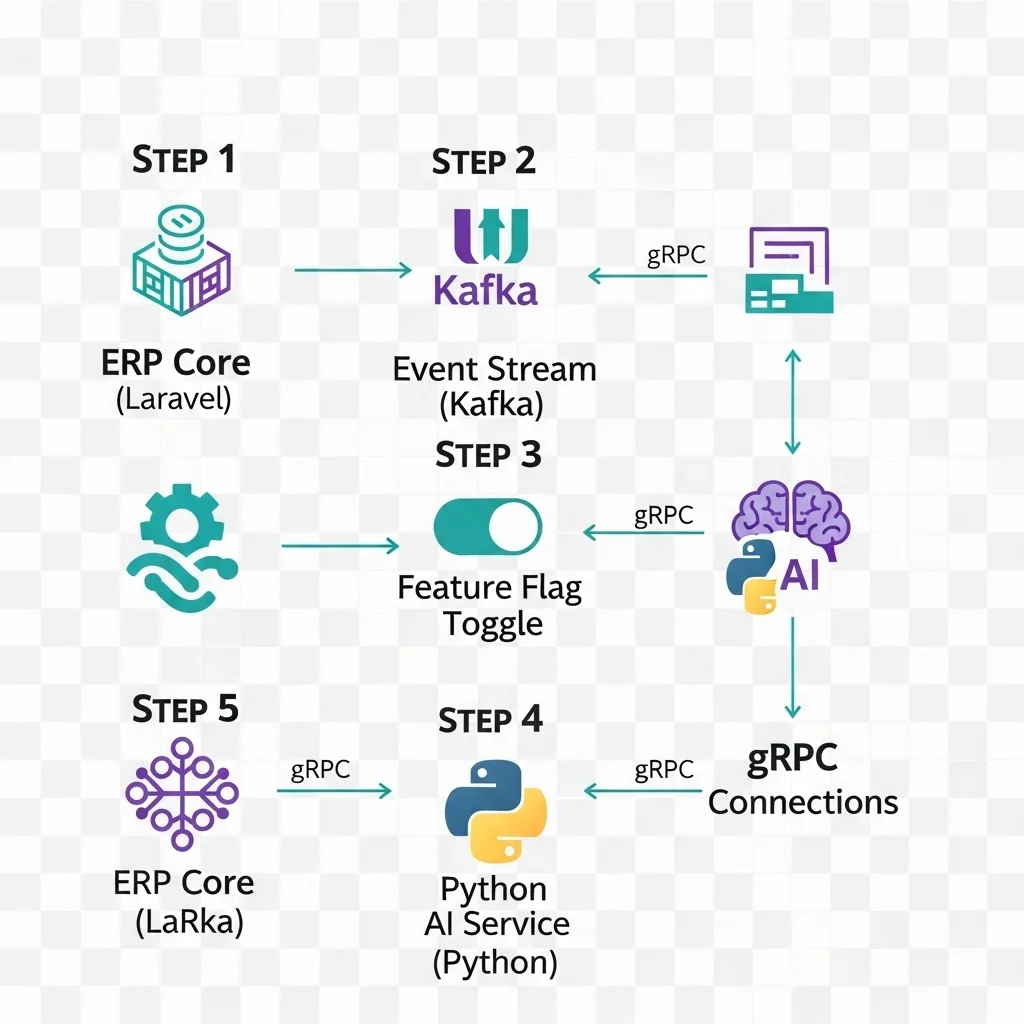

No monolith, but microservices

At Spartner we often build ERP modules as headless services in Laravel. We attach AI components alongside so you can experiment without a big-bang migration.

graph LR

A[ERP Core (Laravel)] -->|REST| B(Data API)

B --> C{Feature Flag}

C -->|true| D[AI Service (Python)]

C -->|false| E[Fallback Logic]

Event streaming

Feature flagging

gRPC microservice

Pro-tip: keep latency < 150 ms, otherwise you'll click "Plan manually" sooner.

Business view: ROI without the hype

From quick wins to cultural change

What I notice is that companies start an AI pilot with great enthusiasm but forget to bring their people along. Operators trust their own Excel sheet more than a black box. Therefore:

Explainability Generate natural-language explanations: "We recommend 18 tonnes of coils because the PMI index is falling and your client X has historically..."

Celebrate small wins Show the team that a 5 % reduction in scrap equals €40 k per quarter.

Iterative learning Feed every wrong recommendation back into the model. It then feels like improving together instead of "AI says so".

You can also license AI modules in a modular way. No multimillion upfront costs, but per user or per 1 000 API calls. CFO-friendly, tech-proof 😉

Data health check

Build a sandbox

Train & validate

Integrate via feature flag

Scale & cultivate

What really sticks with me

AI is no magic wand, but a lever

The metal wholesale market is changing faster than ever. AI + ERP helps you work not harder but smarter. If you start with good data, small pilots and clear KPIs, the rest almost takes care of itself.

Key takeaways:

Why is AI in ERP cheaper now than five years ago?

Cloud GPUs and open-source frameworks such as PyTorch have pushed costs down. In our experience you now often pay per 1 000 requests instead of six-figure licences. :)

Can I feed metal-specific rules into the model?

Absolutely! We feed models with alloy compositions, density factors and even saw speeds. That keeps the prediction realistic.

How do I deal with data silos in my warehouses?

Start by connecting via event streaming or REST APIs. In our experience, 80 % of the value lies in merging those silos.

Is my data safe?

We recommend hosting models on-prem or in a private cloud. At-rest encryption and role-based access are must-haves.

How do I convince the shop floor?

Let AI automate repetitive tasks first, such as order-picking routes. Once operators walk fewer metres they will naturally become ambassadors.

Can AI handle quality inspections too?

Yes, vision models detect surface defects on sheet metal. Integrate camera feeds with your ERP batch numbering and your traceability is complete.

What if the model misses the mark?

Put a fallback in place: "AI score < 0.6? Switch to manual workflow." That keeps operations running.

Which KPI should I measure first?

Our projects show that inventory turnover is the most tangible KPI. You immediately see improvements in cash flow and shelf space.

Curious how AI can make your ERP smarter? Share your challenge in the comments or drop me a DM. Let’s future-proof the metal supply chain together 🔧🤝