How do you take the leap?

From concept to robust series production, without headaches or unnecessary costs.

Automate

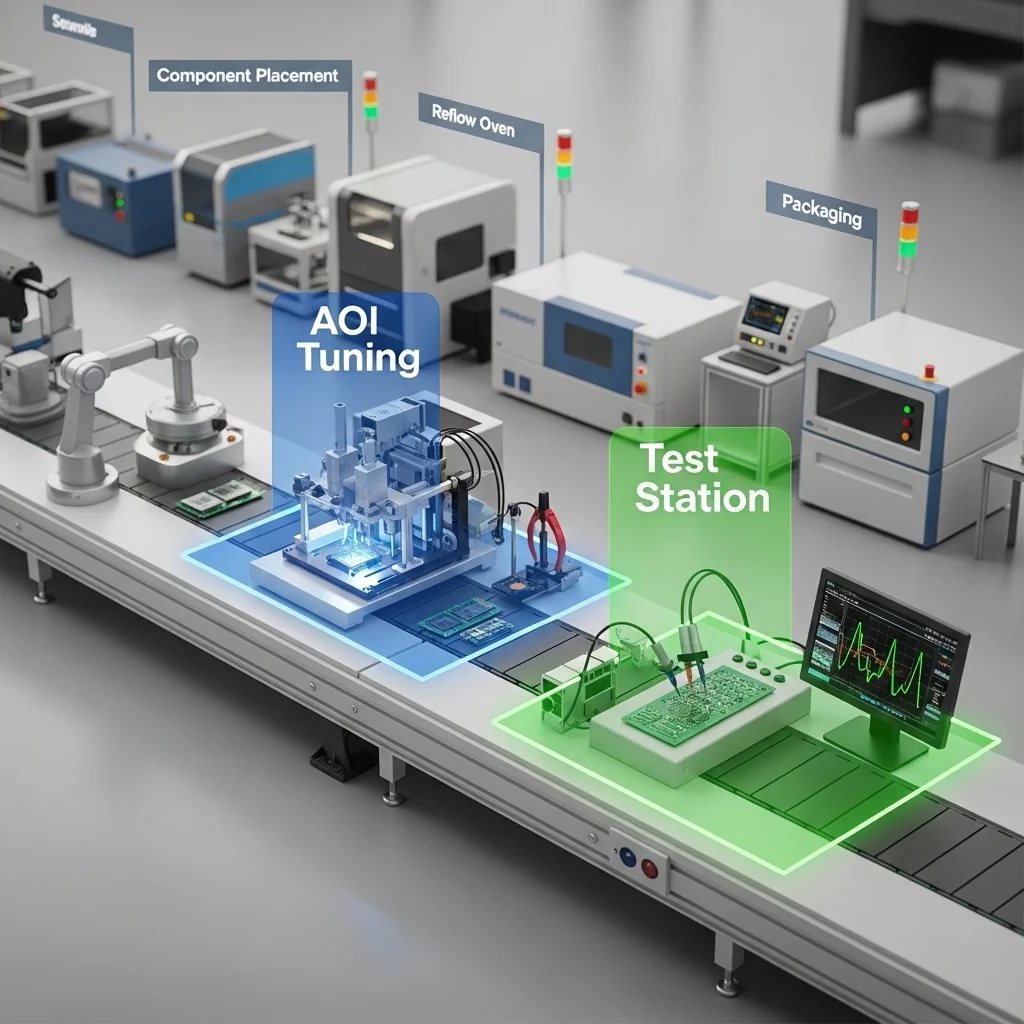

Choose advanced SMT lines with inline AOI inspection; this almost automatically cuts error rates and boosts output.

Integrate

Combine design for manufacturing with inventory management in a single platform to avoid unexpected stoppages.

Innovate

Adopt alternative interconnection techniques such as press-fit or selective soldering, especially for thermally sensitive applications.

Optimise

Proactively carry out DfX reviews and lifecycle analyses so End-of-Life components don’t catch you off guard later on.

A travel log of sorts..

A travel log of sorts.

Why electronics manufacturing remains fascinating

Electronics manufacturing uniquely blends creativity and precision; place one tiny component incorrectly and an entire batch may be scrapped. Yet those who streamline the process achieve lead times that leave competitors jealous.

What you need to watch

From component shortages to ever-stricter certifications, the playing field changes monthly. We notice that companies investing early in supply-chain partnerships experience significantly less downtime.

What this delivers in practice

Faster time-to-market, lower scrap rates and—equally important—happy customers who return.

Unplanned downtime drops by up to 30 %

RMA percentages fall below 1 %

New product introductions happen in weeks instead of months

Step by step, without a rigid roadmap..

Step 1: Define your vision.

The first step may sound soft, yet without a crystal-clear goal—think volumes, markets, certifications—every subsequent decision floats. Take an afternoon, bring stakeholders together and write the criteria literally on the whiteboard.

Step 2: Run a DfX workshop.

Immediately after that vision session, run the drawings through a DfM and DfT matrix. In practice we often see that simply repositioning a connector saves 20 % assembly time.

Step 3: Anchor the supply chain.

Make agreements with at least two component distributors and contractually fix EOL alerts. This alone covers roughly 80 % of supply security.

Step 4: Build a pilot batch.

Don’t skip this, no matter how much pressure there is. Use the pilot to fine-tune AOI parameters, validate stencil designs and calibrate functional tests. In fact, a solid pilot prevents future swap-outs.

Step 5: Scale up & automate.

Once the pilot runs flawlessly, move towards full-rate production. Deploy automated reel tracking so you have component-level traceability—audits always come when you least expect them.

Step 6: Continuous improvement.

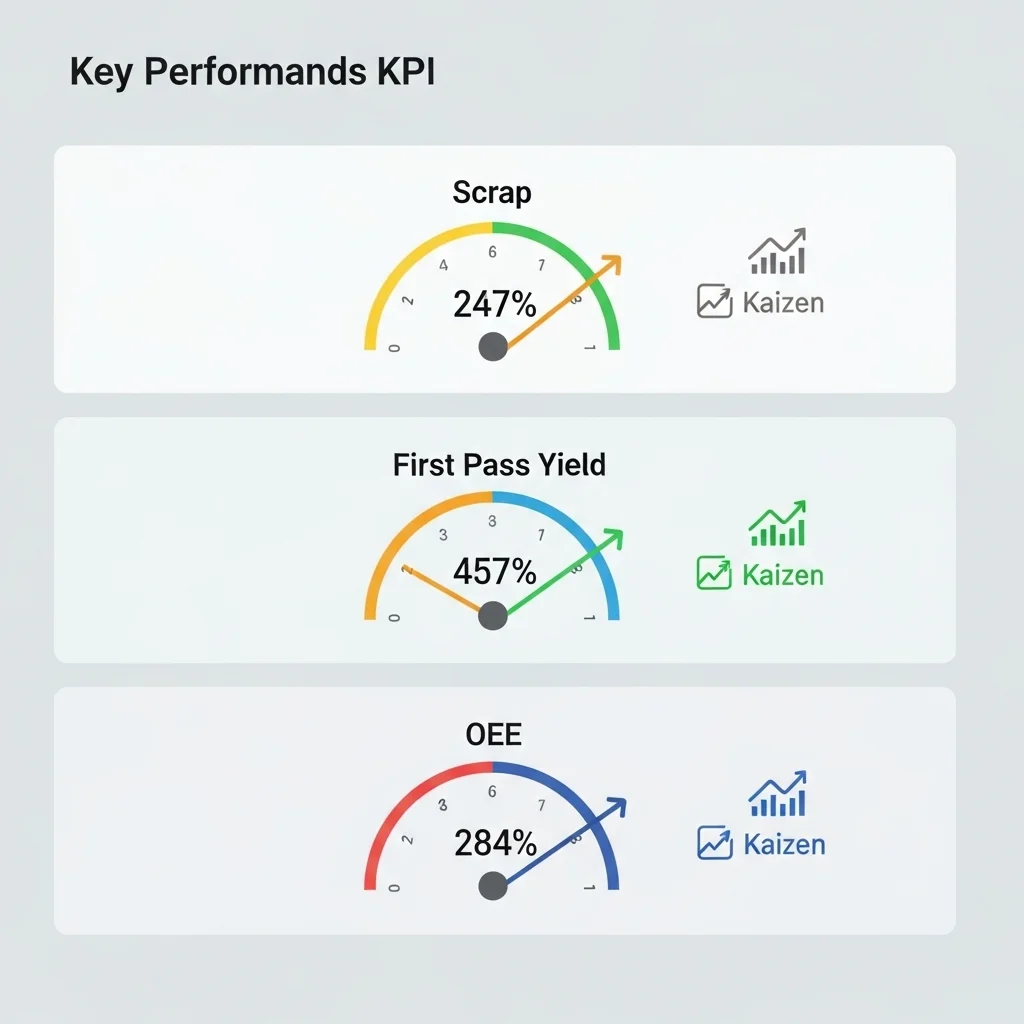

Monitor scrap, first-pass yield and OEE weekly. Build small Kaizen improvements into the rhythm, otherwise performance quietly slips away again.

Ready to get started together?

You now know what goes into electronics manufacturing, yet every project raises new questions. Let’s spar informally about your next PCB, cable harness or complete system—a short conversation could reveal the missing link.

A critical look at cost control.

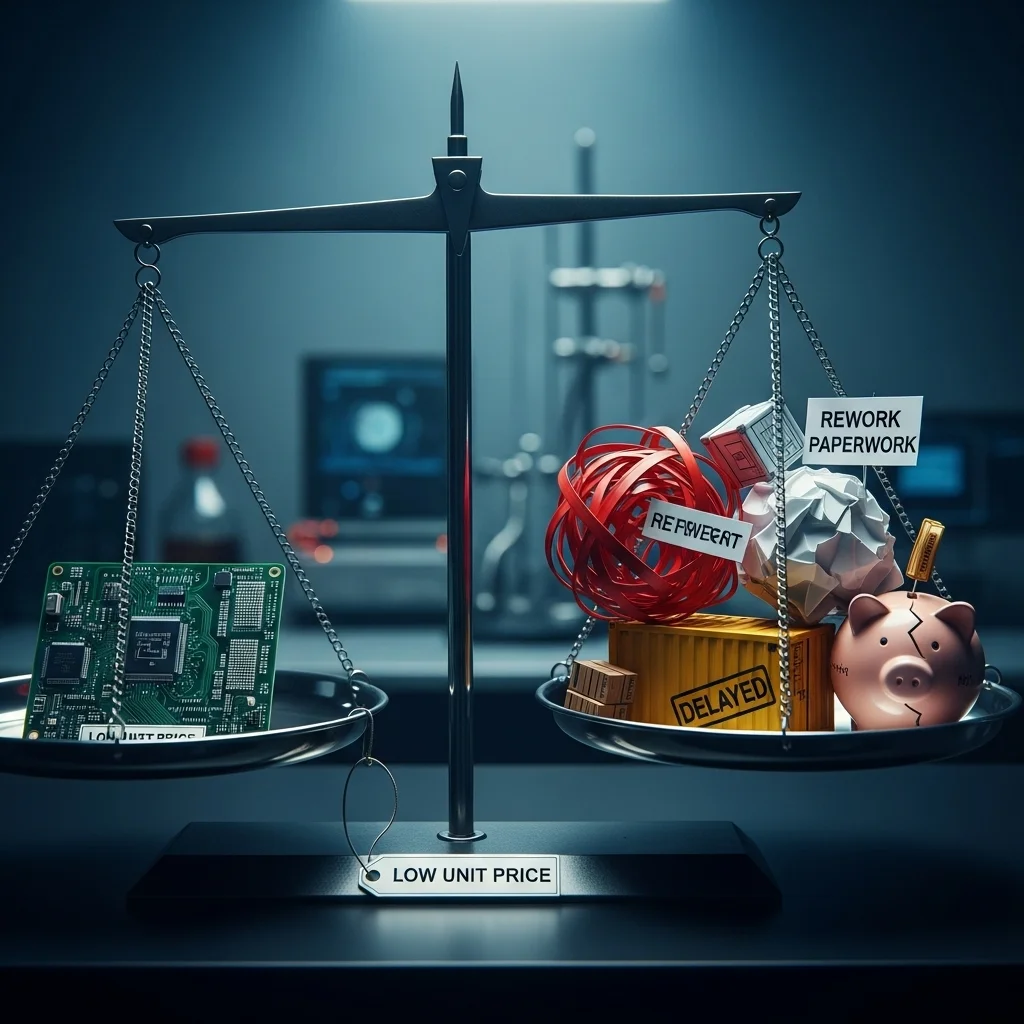

Why the lowest unit price is not always the cheapest

It sounds attractive: have it made somewhere in Asia for a fraction of the price. Yet shipping lead times, import duties and miscommunications often hit harder than expected.

When a PCB needs multiple re-spins due to interpretation errors, you lose not only money but also momentum. What’s often forgotten is the hidden impact on cash flow; stock in transit counts too.

Local versus offshore assembly

Local production gives direct access to operators and engineers, whereas offshore forces you into extensive documentation. We find teams with local partners iterate faster and ultimately spend less.

Practical tips for fault-free assembly.

Small tweaks, big impact

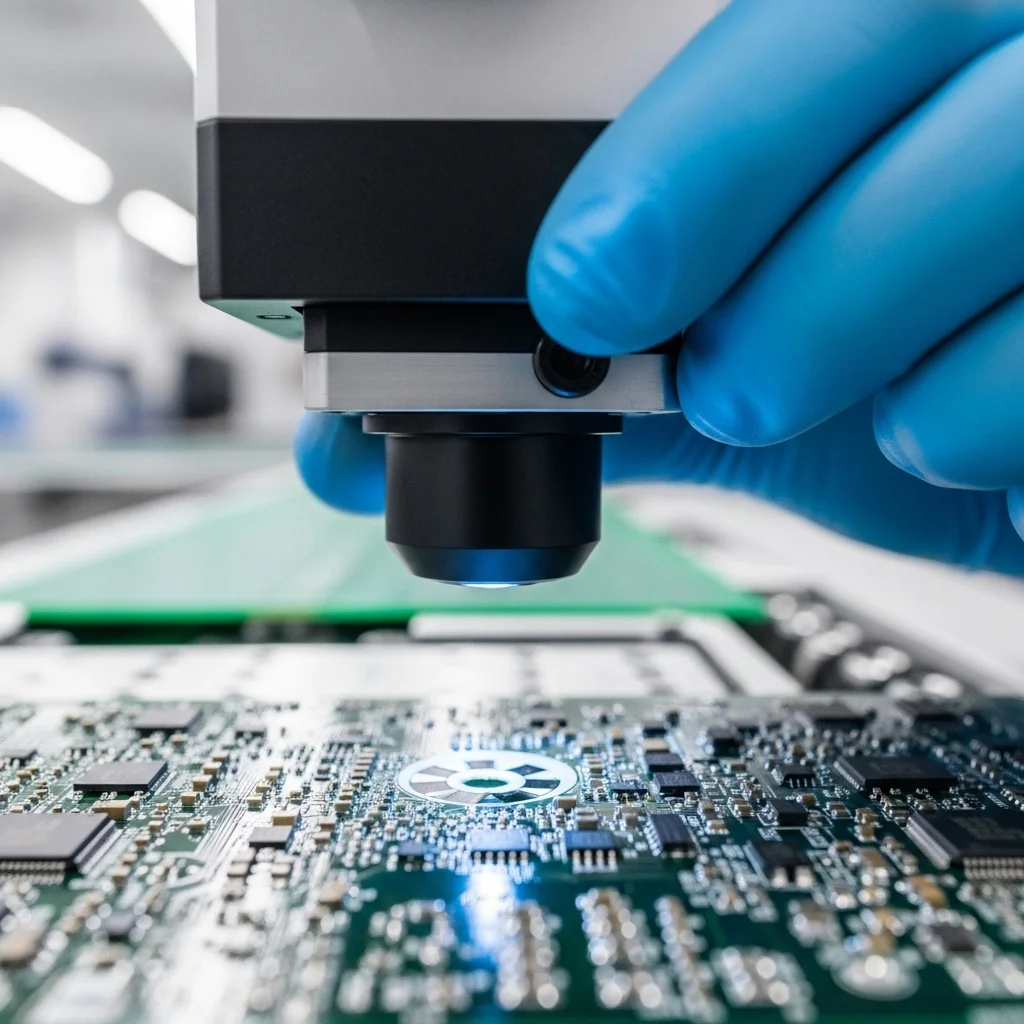

Oversized solder pads can cause tombstoning, while trimming a few micrometres solves the issue. Use a paste-mask reduction of 15 % for 0402 components; such detail saves rework.

Opt for inline AOI with 3D measurement; 2D sees presence but misses height variations. Also, place fiducial marks outside critical RF traces, otherwise they affect impedance.

Fine-tuning temperature profiles

Adjust the pre-heat zone based on board mass, because a thick four-layer FR4 otherwise drags the peak down and leaves you with cold joints.

A look ahead to sustainable manufacturing.

Less waste, more circularity

Young engineers ask themselves, "Can’t it be greener?" Yes—selective soldering avoids flux residue and uses less tin. Plus, closed-loop nitrogen recycling pays for itself within two years.

The good news: more and more EMS partners offer component obsolescence tracking combined with refurb modules. This keeps a product supportable for longer without new PCB runs.

From linear to circular

Using disassembly-friendly press-fit connections allows valuable ICs to be reused easily. In practice that yields up to a 40 % reduction in e-waste—not bad at all.

How fast can I move from prototype to series production? 🙂

Lead time strongly depends on design complexity and component availability; on average we see companies with a tight DfX process running series within 6-8 weeks.

Is SMT always better than THT? 🤔

Not necessarily. SMT is more compact and quicker, but THT provides mechanical strength for heavy connectors or high-temperature applications. A hybrid approach often wins.

How do I handle component shortages?

Work with multiple distributors, enable EOL alerts and plan alternative components in the design. It can be frustrating when a critical IC suddenly isn’t available, but this keeps you flexible.

Which certifications are truly necessary?

For general electronics, ISO 9001 is usually sufficient; in medical or automotive markets you’ll need ISO 13485 or IATF 16949 respectively.

What does an AOI system actually cost? 💸

Prices range from €30 k to €150 k depending on 3D capabilities. You quickly earn it back through lower rework costs.

Can I combine sustainability with low costs?

Yes—think energy-efficient ovens and closed-loop nitrogen. An upfront investment but lower operating costs in the long run.

How important will traceability be in 2025?

Extremely important. Customers and regulators alike expect component-level tracking. It also facilitates root-cause analyses when something goes wrong.

What if my design isn’t production-ready yet?

Schedule a design review with an EMS partner; small layout tweaks prevent major production errors.

Is it worthwhile to produce in-house? 🏭

Only when your volumes are large, know-how is available and you’re prepared to keep investing in machinery. Otherwise you’re better off with a specialised partner.

What role does software play in electronics manufacturing?

ERP and MES systems connect purchasing, production and quality data. Without that link you lose oversight, especially with multi-site production.

.webp)