Why accelerate now?

Climate targets are approaching faster than expected—action is no longer a luxury

Automate

Using design systems, parametric tooling and industrialisation, you break projects into repeatable modules. That cuts failure costs and saves time.

Integrate

Combine insulation, services and façade finishing in one prefab skin. Fewer on-site activities and less disruption for residents.

Monitor

IoT sensors provide live feedback on energy use and comfort, turning every dwelling into a mini test lab.

Scale up

What works in one neighbourhood can be rolled out to ten others with minimal tweaks. The secret lies in standardisation plus a clever variable part.

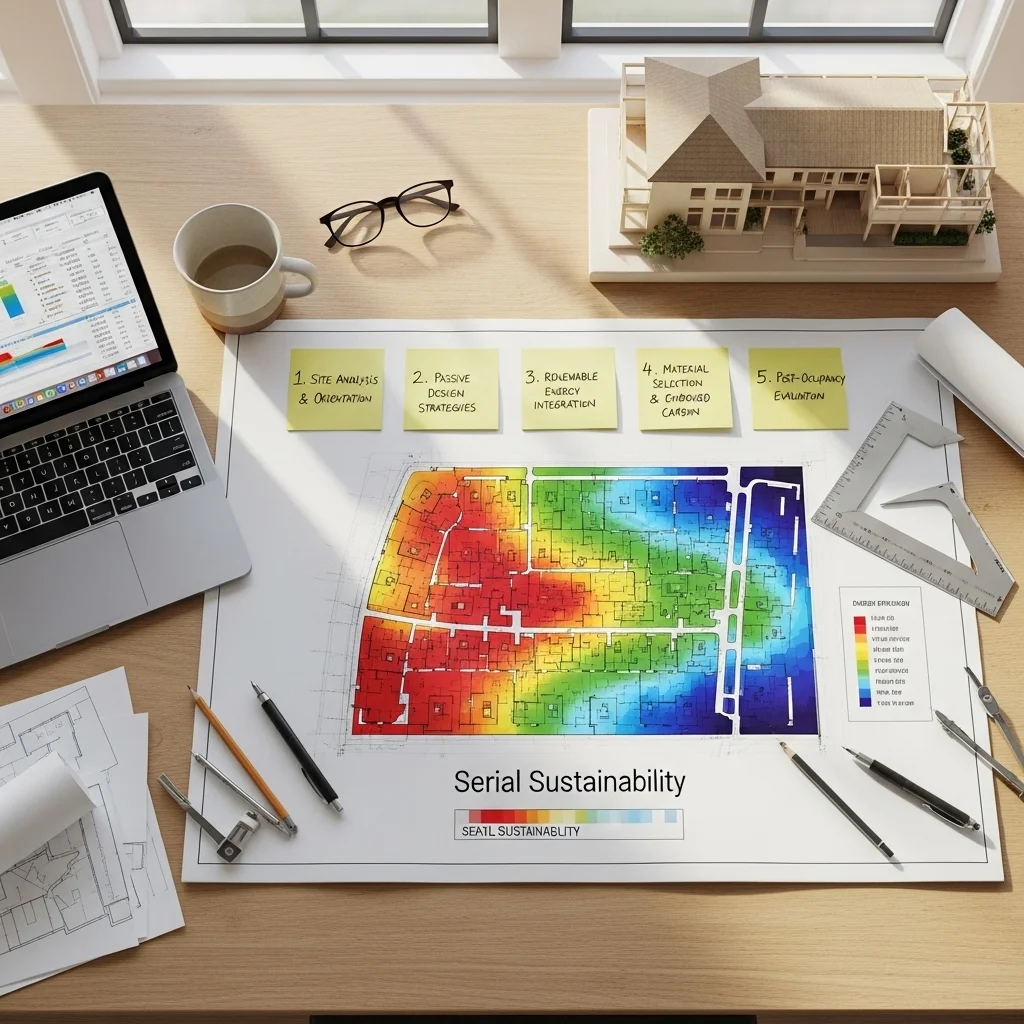

Serial sustainability at a glance.

A Swiss Army knife for construction

Integration is king

Many projects derail because insulation, services and user behaviour are viewed in isolation. Serial sustainability forces you to design them integrally: one BIM model, one logistics chain, one quality check.

Speed through repetition

I often notice that teams are afraid of copy-paste construction. In practice, residents appreciate predictable planning—and housing associations finally gain control over budget and performance.

Data as a turbocharger

By feeding delivery data and resident feedback straight back into the design kitchen, you create a learning loop that makes every next tranche smarter.

Lower failure costs, greater certainty

Shorter execution time—days instead of weeks

Consistent quality across the entire housing stock

A growth path to net-zero without the headache

Step-by-step plan for serial sustainability.

An overview of the key phases on the road to serial sustainability.

Step 1: Analyse the housing stock.

Start with the big numbers: year of construction, typology, current label. Add infrared scans and blower-door tests. This reveals the quick wins and which series of homes suit a single standard solution.

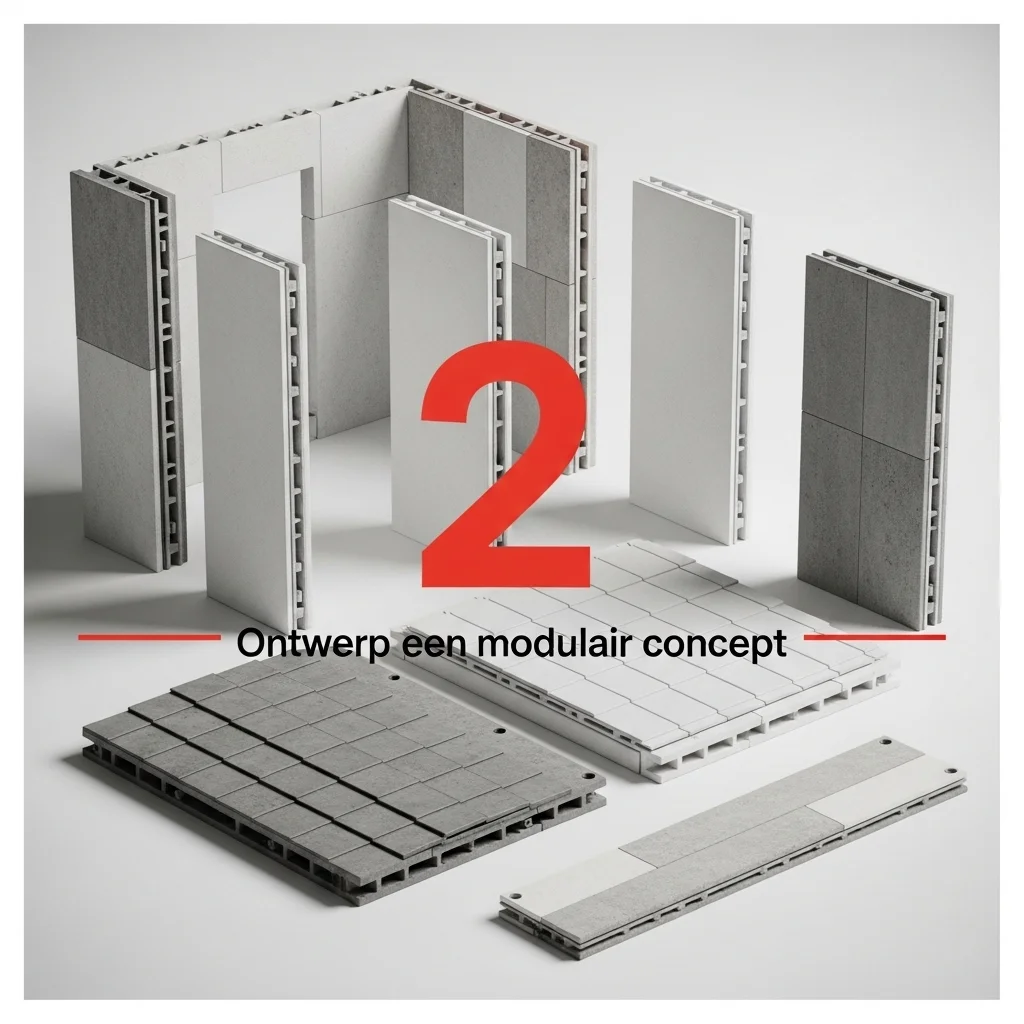

Step 2: Design a modular concept.

Choose a basic package (insulation, airtightness, ventilation) and an optional upgrade (PV, heat pump). By thinking in modules from day one, you can easily scale or fine-tune later.

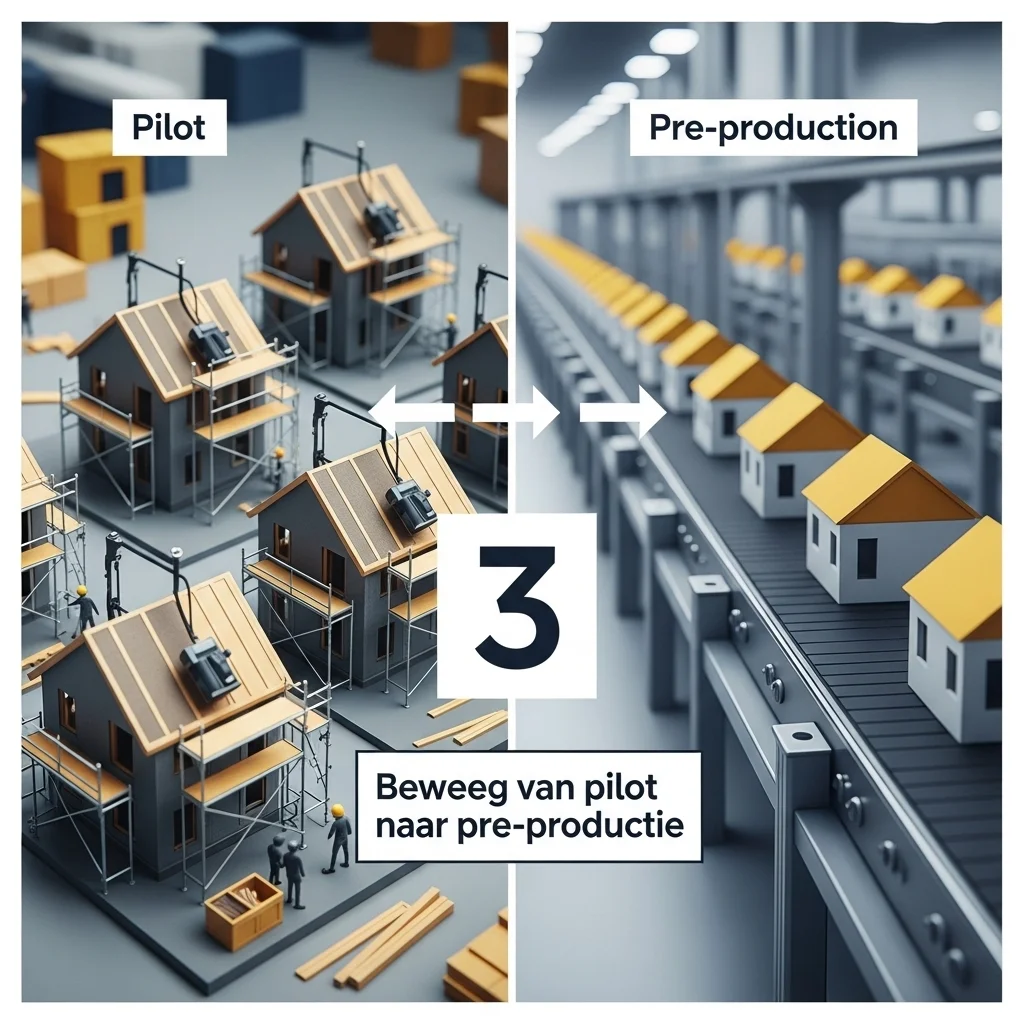

Step 3: Move from pilot to pre-production.

Test the concept on a small block of homes. Gather data, tweak details—think window size or pipe routes—and then create production drawings for series manufacturing.

Step 4: Secure a tight supply chain.

Set clear agreements with prefab partners, carriers and installation teams. A just-in-time schedule prevents waiting times and closed streets. Residents, frankly, sleep a lot better.

Step 5: Monitor, evaluate, improve.

Install sensors, hold kitchen-table talks with residents and perform periodic performance checks. Feed the insights straight back to your design team so tranches two and three are even sharper.

Let's accelerate together

Do you already know exactly which neighbourhoods you want to tackle next year—yet still doubt the route? Let's grab a coffee and sketch the first outlines of a serial masterplan together.

A critical look at standardisation

Copy-paste or customised with a twist?

The term 'serial' can make some professionals fear bland uniformity. Understandable—no one wants to live in a clone house. Yet it's not about identical homes but about identical processes.

Where is the flexibility?

Façade finish and colour scheme can vary per street

Installation packages usually come in three capacity variants

Interior finishing always remains the resident's choice

As mentioned earlier, it is about repeatable—not rigid—solutions.

Practical tips for a flying start

What you can do tomorrow

Create a heat map of your portfolio and rank by energy urgency.

Select one dwelling typology with the highest numbers—often a 1960s walk-up or terraced house.

Organise a co-creation session with installers, prefab manufacturers and resident representatives.

Translate the outcome into a modular concept design including cost estimate and schedule.

Make smart use of subsidies; consider the Corporate Sustainability Incentive Scheme.

Looking ahead: digital twins and AI

Renovating smarter without demolition

Digital twins—virtual copies of your properties—allow you to run scenarios before the first screw is turned. Suppose AI predicts that a hybrid heat pump offers the best ROI in Street A, while Street B is better off all-electric. Your design decision is immediately backed by data rather than gut feeling.

What's coming?

Real-time energy simulations per dwelling type

Predictive maintenance based on sensor values

Automatic material optimisation for minimum CO2 footprint

In fact, suppliers are already working on robot-guided façade installation. It may sound futuristic, but the first pilots are running—and it works.

Frequently asked questions

😅 Why is serial sustainability actually cheaper?

Repeatable processes minimise design hours and failure costs. Materials are bought in bulk and prefab-assembled, reducing on-site labour costs.

🌡️ Does this not create cookie-cutter homes?

No. The processes are standard, not the aesthetics. Façade panels, colours and systems are modularly adjustable so that streets keep their own character.

🚚 How much disruption do residents experience?

In a serial trajectory the façade upgrade often takes only one or two days per home. Thanks to just-in-time logistics the street remains accessible and residents can usually stay at home.

🔌 Is net-zero always achievable?

Not always immediately. The serial route provides a growth path: insulate and seal first, then upgrade systems and add PV. This spreads investment and risk.

📊 How do you monitor performance after handover?

With IoT sensors for temperature, humidity and energy use. The data is analysed anonymously and fed back to both residents and the project team.

💶 Are subsidies available?

Yes, consider schemes like SVOH or the Housing Impulse. Availability varies, so always check the latest rules—or have a specialist assist you.

⏱️ How long does a project take on average?

It depends on scale, but with prefab skins a block of ten homes can be finished within two weeks. Preparation does take a few months.

🤔 What if a house falls just outside the standard type?

You can often use a plus-module—say an adjusted window size or extra insulation—without overhauling the entire design.

.webp)